Accurate and Efficient Order Picking & Packing Software

Khaos Control’s warehouse functionality ensures that order picking is carried out efficiently and accurately. The order picking process involves significant labour costs and can impact customer satisfaction levels. Having the right picking software solution in place is vital for the smooth running of your warehouse.

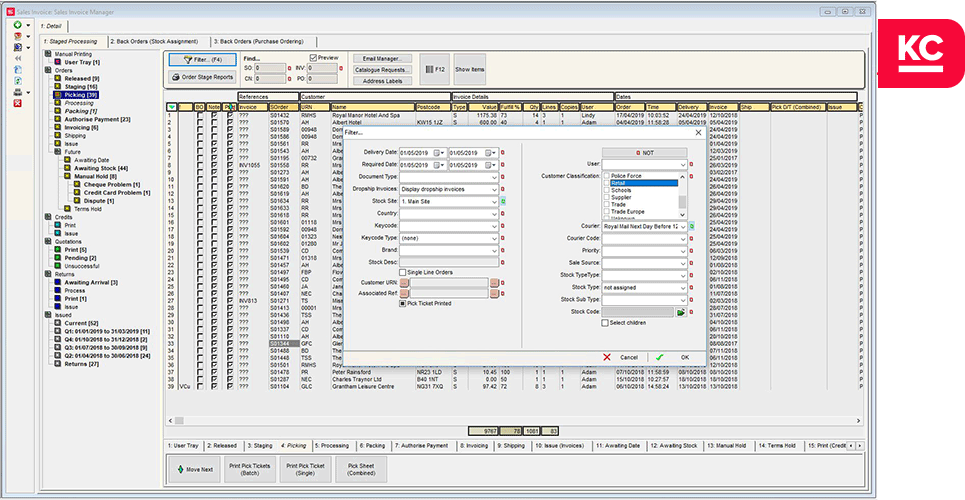

Avoid dead time on your picking line

Our picking software allows you to pick orders individually or in batches, enabling your staff to pick items for multiple sales orders in a single sweep of the warehouse. With software in place, less time is wasted, productivity is increased, and more time is given to other high priority tasks within your process.

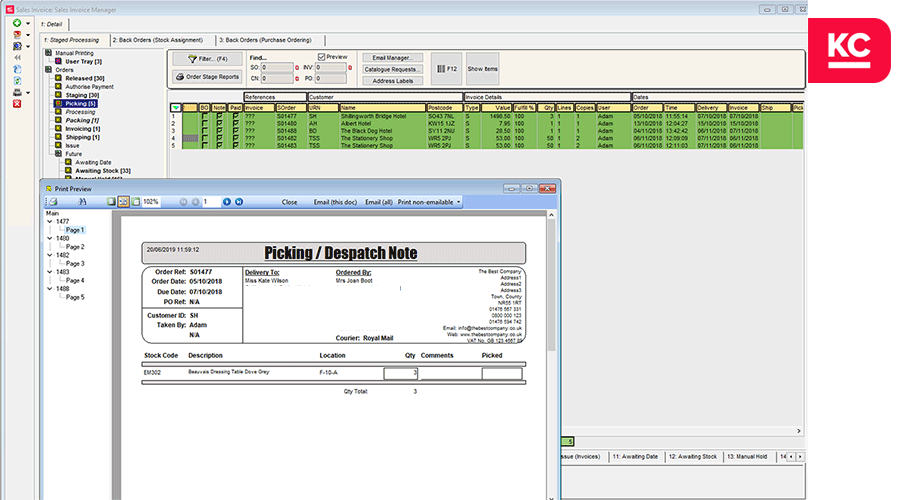

Professional and branded paperwork

Khaos Control allows all documentation to be customised to suit your brand. That means a consistent, and professional experience for your customers from start to finish.

Producing clear, branded picking and despatch documentation also means your pickers and packers have all the information they need to ensure that the right products go to the rights customers – every time.

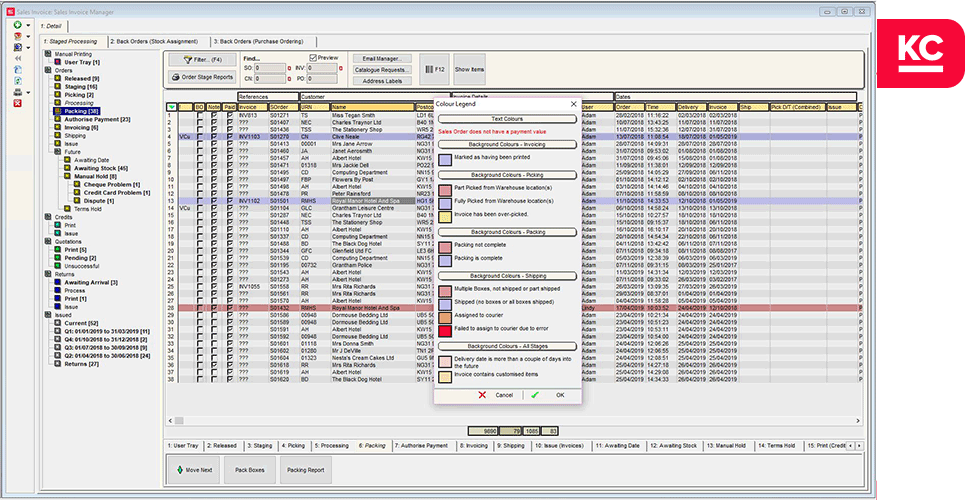

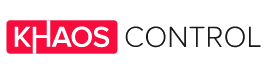

Give your customers levels of priority

Our picking software means urgent orders can be easily prioritised during the pick process, ensuring your customers are dealt with as quickly and efficiently as possible. For some, that might mean asking the system to allocate purchase orders to a specific list of customers, as soon as certain stock is available. If you were a company supplying medical equipment to the NHS for example, you could prioritise these orders as and when necessary.

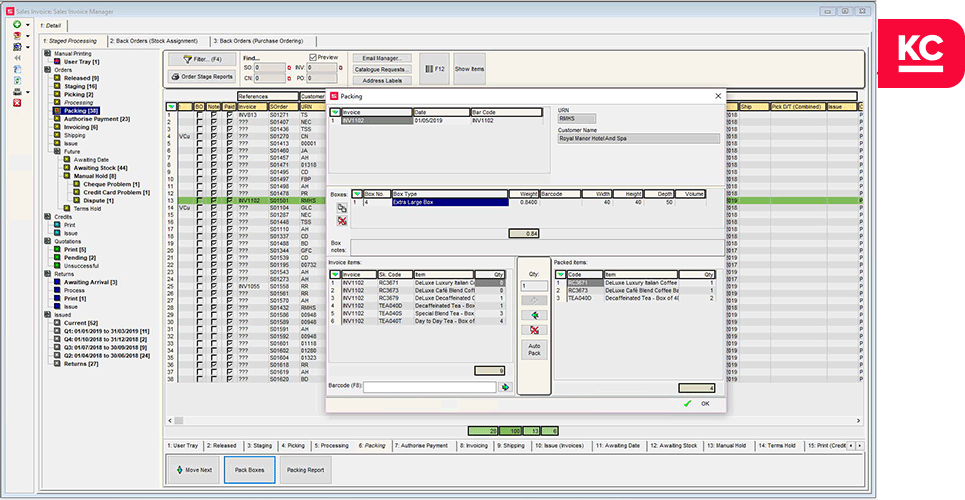

Keep your warehouse lines running efficiently with packing software

Knowing how much packaging you use to ship your items and ordering the right kind can go a long way to controlling the costs behind your orders, and packing software is just the thing to keep that on track. Being in full control of your pick pack and dispatch line also means making sure customers receive the same great service, every time.

Control your packaging inventory

Controlling the inventory levels of your packaging items can significantly speed up your packing process, instantly eliminating the prospect of running out of certain types of packaging. A clearer insight into packaging levels means a clearer insight into forecasting your requirements and reporting on them for your busiest seasons.

The right packaging for the right item

Our packing software allows automated packaging selection, meaning you can link specific products in your inventory to their own specific packaging needs. If you’re a business that deals with delicate or fragile items, you can ensure that items are arriving at their destination well protected and secure. Equally, this is a feature great for businesses trying to more conscious about wasted packaging/ reducing the amount of packaging used in operations.

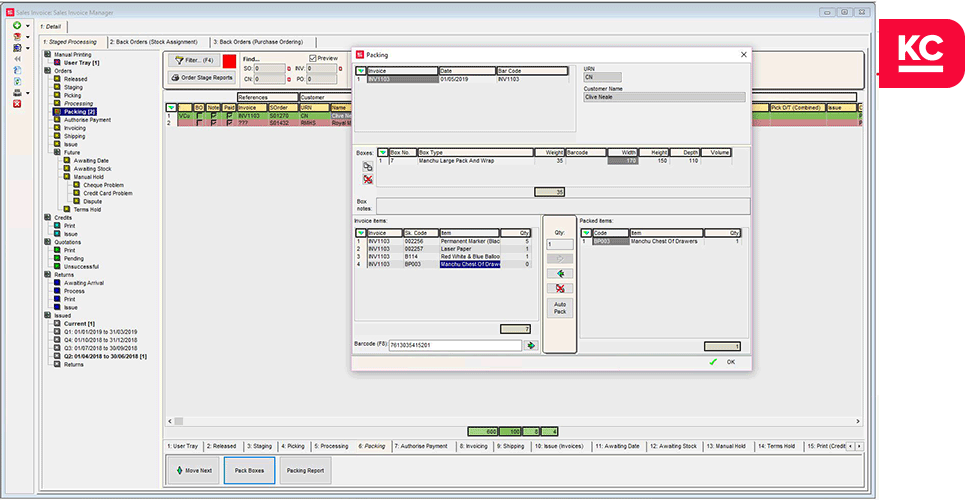

Accuracy is key

Accuracy in your picking and packing process is key to a successful ecommerce business – one mistake can lead to customer dissatisfaction, as well as an expensive logistics problem. Packing is labour intensive work where the pressure for fast performance combined with its repetitive nature causes mistakes. Our automated packing software is there to alleviate pressure, and increase productivity.